The movement of the motor bearings causes a lot of friction in the engine elements. Engine Bearing Failure The bearings must be in good condition to provide this support. Engine rolling problems have an impact on the performance of the vehicle. As a result, it has been essential to understand the symptoms of motor failure because they will help you determine when it’s time to see a repair.

The engine bearings are produced from some of the most durable materials available. However, they are subject to failure because of high temperatures and stress in the combustion chamber. They are likely to wear because of their role to minimize friction.

The engine bearings can fail for a variety of causes. situs judi slot terbaik dan terpercaya no 1 Extreme operating conditions and severe loading are two factors that contribute to this failure. It is recommended to maintain the bearing in excellent operating condition and that the worn bearings be replaced.

The failure of the motor bearings can cause major problems with the vehicle. We will move on to some of the most typical indications of failed engines bearings, their causes, and how to avoid this common engine problem. If you notice any of the symptoms mentioned, we recommend that you search online service and car repair garages and schedule an appointment with a technician to diagnose and repair the problem.

Symptoms of motor bearings failure

The most common cause of Engine Bearing Failure is a damaged motor. There are a number of signs indicating that the engine bearing is defective. If you leave the problem unattended for a prolonged period, it will wreak havoc on other engine components.

It may be necessary to replace the complete engine in certain circumstances. As a result, it is essential to keep an eye on these symptoms and treat them as quickly as possible. Just look for reading garages and reserve an appointment with a qualified car mechanic.

Here are some indicators for warning motor bearings failure to keep an eye on:

1. Noisy engine

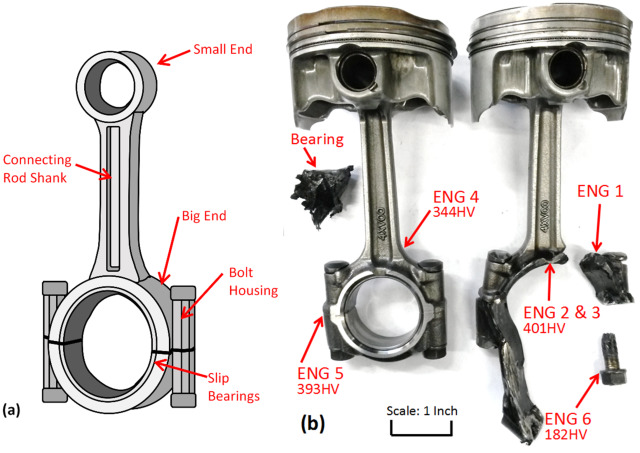

To enjoy peace and tranquility, every motorist desires a journey gently. The only noises you would like to hear are those who came from the stereos of your car. However, when the bearings wear out, a strange engine rolling noise will emerge. The striking rod is the most common symptom of motor rolling failure. It makes a noise in the engine comparable to the trains and lifts of the valve. This occurs as a result of excessive clearance caused by rolling wear. Following the poor end failure of the end of the rod, it takes counter to the crankshaft of the vehicle, causing a grinding contact.

2. Belts that worn and a noisy transmission

A bearing has two main faces: one for the outer ring and one for the inner ring. The large support surface is the first, and it is prone to wear and slope. The face bearing the thrust is the second. The main bearing works with the crankshaft, but the bearing of the thrust helps control the movement of the transmission. The support face of the thrust maintains the transmission moving forwards backwards, which causes it above time. The worn thrust bearings can cause the crank stroke to the back, bringing the torque converter into transmission. When there is enough room on the stem logs, such an event is common. It is the source of the strange noises from the diffusion. Apart from this, the belts can wear excessively on the edge due to advanced and rear movements caused by worn thrust bearings. In addition, the metal debris generated by the action of the torque converter can adhere to the filter and obstruct it. The fluid loses the pressure accordingly and the fuel pump finally fails.

3. Low oil pressure

When an engine motor starts failing, one of the first symptoms you will notice is a loss of oil pressure. Vehicle oil pumps provide a specified fluid volume and 20 gallons per minute seem to be the norm. Leaks in the engine, such as those between the motor bearings and the hydraulic fluid, can nevertheless cause a reduction in the oil pressure. This occurrence occurs following the oil levin